Direct-to-film (DTF) transfers are revolutionizing custom design creation with their cutting-edge printing method. This technique bypasses traditional intermediates by directly applying ink to fabrics using heat and pressure, resulting in vibrant, long-lasting prints with intricate detail. DTF's versatility allows for complex patterns on diverse materials while preserving product integrity, making it a popular choice for high-quality custom items at scale. Heat transfer vinyl (HTV) offers an alternative, providing greater versatility and cost-effectiveness for various applications. When choosing between DTF and HTV, consider factors like durability, quality, volume, and material compatibility to determine the best fit for your project.

“In the realm of custom printing, Direct-to-Film (DTF) transfers and Heat Transfer Vinyl (HTV) offer distinct approaches to creating durable designs. This article explores these two popular methods, providing a comprehensive guide for enthusiasts and professionals alike. From the intricacies of DTF printing, its unique benefits, and cost-effectiveness, to examining HTV’s alternatives and durability, we delve into the factors that matter most when choosing between DTF transfers and heat transfer vinyl for your next project.”

- Understanding Direct-to-Film (DTF) Transfers: A Quick Overview

- How DTF Transfers Are Made and Their Unique Advantages

- Exploring Heat Transfer Vinyl: Alternatives to DTF

- Comparing Quality and Durability: DTF vs. Heat Transfer Vinyl Prints

- Cost Analysis: Which Option Offers Better Value for Money?

- Choosing the Right Method: Factors to Consider for Your Project

Understanding Direct-to-Film (DTF) Transfers: A Quick Overview

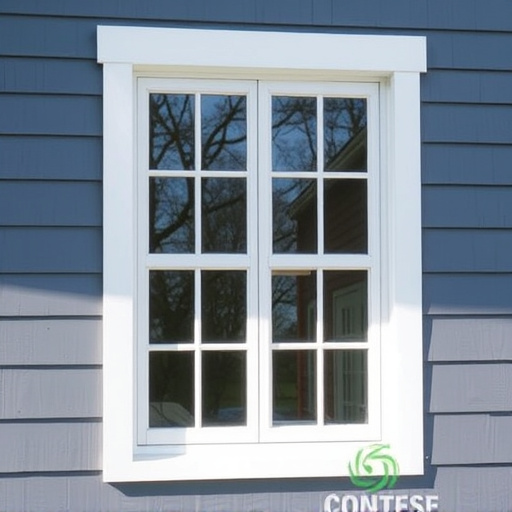

Direct-to-Film (DTF) transfers are a cutting-edge printing method that’s revolutionizing the way we create custom designs on various surfaces, from clothing to accessories. This innovative process involves transferring printed ink directly onto fabric or other materials using heat and pressure, eliminating the need for intermediate media like paper. DTF offers several advantages; it delivers vibrant, durable prints with exceptional detail, making it a top choice for high-quality, long-lasting designs.

DTF Printing is particularly popular among businesses and enthusiasts due to its efficiency and versatility. It allows for complex, intricate patterns and can accommodate various material types, ensuring that final products maintain their visual appeal and structural integrity. As DTF technology continues to advance, it’s becoming more accessible, making it a go-to option for creating unique, custom items at scale while maintaining superior print quality.

How DTF Transfers Are Made and Their Unique Advantages

Direct-to-film (DTF) transfers are a cutting-edge printing method that offers a unique and efficient approach to applying designs to various surfaces. The process involves precisely placing the design onto a film, which is then heated and pressed against the desired material, such as fabric or wood. This technique ensures a crisp and accurate transfer, making it particularly appealing for custom clothing, accessories, and craft projects. One of the primary advantages of DTF transfers is their ease of use; they can be applied with minimal equipment, making them accessible to both professionals and hobbyists.

Additionally, DTF prints provide an array of benefits. They offer a wide range of color options and excellent durability, ensuring that designs maintain their vibrancy and quality even after repeated washings or exposure to the elements. This method also allows for intricate detail and fine lines, enabling complex artwork and text to be reproduced with precision. Moreover, DTF transfers are versatile, suitable for various media types, from textiles to paper and plastics, making it a popular choice for those seeking a dynamic and adaptable printing solution.

Exploring Heat Transfer Vinyl: Alternatives to DTF

Heat transfer vinyl (HTV) offers an exciting alternative to direct-to-film (DTF) transfers in the world of printing and design. While DTF has gained popularity for its ease and speed, HTV provides a versatile and cost-effective solution with a unique set of advantages. This method involves applying heat-activated ink onto a carrier sheet, which is then pressed onto various materials like fabric, allowing for intricate designs and vibrant colors.

Unlike DTF, which is limited to specific types of surfaces and often requires specialized equipment, HTV can be used on a broader range of fabrics and materials, making it suitable for custom apparel, accessories, and even home décor projects. Its flexibility in design possibilities and the ability to achieve high-quality prints on demand make heat transfer vinyl an attractive option for businesses and individuals looking to create personalized items efficiently.

Comparing Quality and Durability: DTF vs. Heat Transfer Vinyl Prints

When comparing direct-to-film (DTF) transfers with heat transfer vinyl prints, durability and quality are key factors to consider. DTF printing offers exceptional clarity and vibrancy in colors, making it ideal for high-quality applications like promotional items and apparel. The process involves applying ink directly onto a film, which is then transferred to the substrate. This method often results in long-lasting prints that can withstand washing and everyday wear.

On the other hand, heat transfer vinyl (HTV) prints provide a different level of durability. While still durable, HTV uses a thin layer of vinyl with ink sealed inside, which is heated to transfer the design onto fabric. This method may not achieve the same level of color vibrancy as DTF, but it excels in adapting to various fabrics and surfaces. Over time, heat-applied prints can slightly degrade under extreme conditions, unlike DTF transfers that remain more consistent even after frequent use.

Cost Analysis: Which Option Offers Better Value for Money?

When comparing direct-to-film (DTF) transfers and heat transfer vinyl, cost is a significant factor in determining which option offers better value for money. DTF printing involves applying designs directly onto film, which is then transferred to the desired surface. This process can be more affordable for smaller orders or one-off projects due to lower setup costs. The direct application to the substrate also means there’s less wastage, making it an economical choice for creating unique, custom prints.

On the other hand, heat transfer vinyl requires a more intricate setup with a heat press machine. While this initial investment might be higher, it allows for larger production runs and more complex designs at a lower per-print cost. The durability of heat-applied vinyl is also superior, making it a preferred choice for items intended for prolonged use or exposure to harsh conditions. For businesses or individuals seeking volume efficiency and long-lasting results, heat transfer vinyl is often the more cost-effective option in the long run.

Choosing the Right Method: Factors to Consider for Your Project

When deciding between direct-to-film (DTF) transfers and heat transfer vinyl for your project, several factors come into play. Each method has its unique advantages and limitations, so understanding your needs is key to making an informed choice. DTF printing offers a straightforward, cost-effective solution for creating high-quality prints on various materials, especially when dealing with intricate designs that require sharp details. It’s ideal for smaller runs or one-off projects, as it provides excellent color accuracy and a durable finish.

On the other hand, heat transfer vinyl allows for more versatility in terms of fabric types and allows for larger batch production. This method is perfect for creating custom apparel or accessories with vibrant, long-lasting colors that can withstand frequent washing. While DTF transfers might be limited in terms of material compatibility, heat transfer vinyl offers a broader range of options, making it suitable for both light and heavy fabrics. The choice ultimately depends on your project’s scale, desired outcome, and the type of materials you plan to work with.